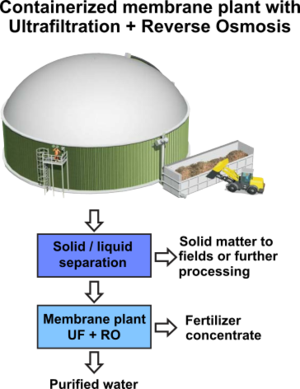

Treatment of liquid digestates resulting from biogas plants by means of ultrafiltration and reverse osmosis

Biogas plants designed for the further processing of organic waste, liquid manure or renewable raw materials produce digestate that needs to be disposed of. If this waste is not used for agricultural purposes, it is usually separated into solid and liquid phases by means of screw presses or centrifuges (decanters). The resulting material consists of solids (containing high amounts of phosphate) and liquid substrate containing high amounts of nitrogen.

Where possible, the liquid phase is reused as process water. Surplus material can be used as nutritious fertiliser that provides reduced odour and improved plant availability. If there are no appropriate agricultural areas in the vicinity of the biogas plant, major expenses for storage and transport to remote sewage farms may occur.

Where to dispose of the excess liquid digestate?

For the discharge of liquid digestates into water bodies or public sewage systems, legal limits apply. These values can only be achieved by implementing certain technical processes. In practical applications, membrane technologies have proven to be particularly suitable for this process. By using process combinations such as ultrafiltration (UF) and reverse osmosis (RO), the liquid digestate is separated into two material flows at a ratio of 2:1. The separation is done using approx. 2/3 permeate (purified water) on one side and approx. 1/3 concentrate on the other side. The permeate can be discharged and the concentrate can be used as a high-quality liquid fertiliser.

Advantages of digestate treatment with membrane technology:

- Reduction of volume to approx. 1/3 of the inlet volume:

- Reduced demand for storage basins and reduction of transport costs

- Compliance with legal requirements:

- Due to the fact, that the RO membranes offer high retention, the specifications according to annex 23 of the German Waste Water Ordinance can be fulfilled, so that direct discharging of the permeate is possible.

- Operational safety thanks to UF+RO:

- The physical separation processes ensure safe and reliable operation, regardless of deviations in the water composition

- High-quality products

- High-quality, concentrated liquid suitable for agricultural purposes

- Water without residues suitable for internal use (cleaning, or process water containing reduced amounts of NH4+)