Reverse Osmosis Plant for Leachate Treatment

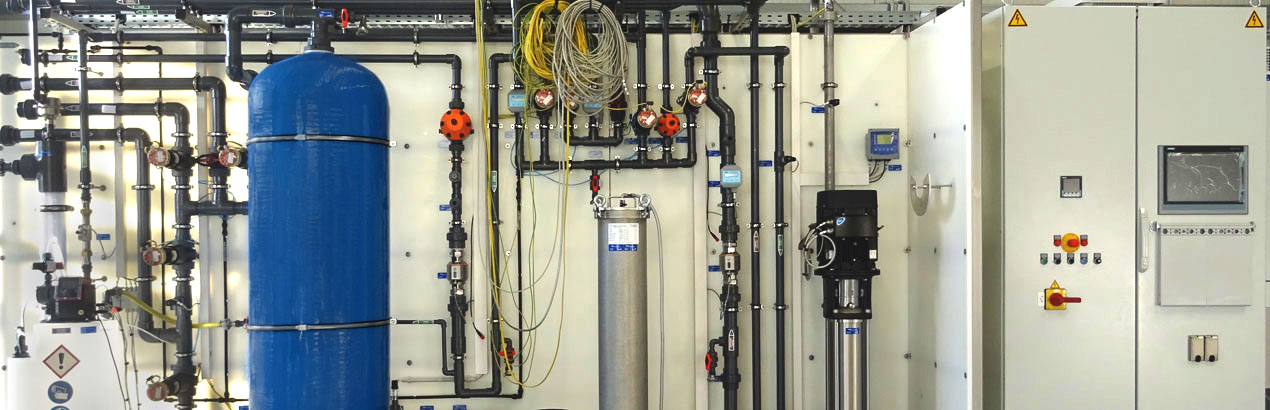

Since 2013 TDL Energie GmbH has been successfully manufacturing and operating reverse osmosis plants for treatment of landfill leachate on sites in Europe, Africa and South America such as Brazil. Our plants are characterized by high availability, user friendliness and a high degree of automation. The plants are designed and manufactured at our own production site in Germany and installed and commissioned on site by our experienced team of engineers. TDL Energie GmbH reverse osmosis plant can be either constructed as containerized modular unit or is setup inside a lightweight hall, depending on the required application type.

Standard sizes of TDL Energie GmbH RO plants can treat leachate inflows of 50 m³/h up to 300 m³/h. Plants with higher flow rates can be built on customer request for every special case of leachate composition, temperature and operating pressure needed for the treatment of waste water. Due to flexible options of the plant container the plants can be adjusted to fluctuating leachate volumes quickly and at low cost. We also have a pool of rental plant should you need a temporary solution for your landfill site.

We also have a pool of rental plants should you need a temporary solution for your landfill site.

Basic principles of reverse osmosis

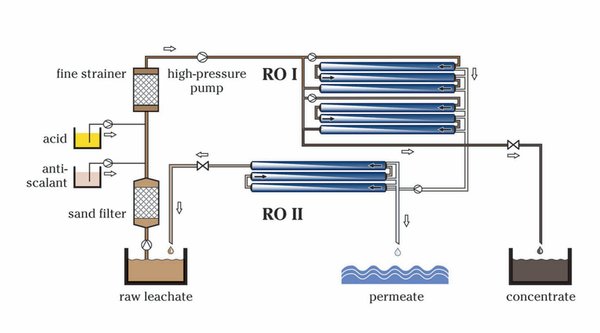

If two solutions of different concentration are separated by a semi-permeable membrane, the solvent, in most cases water, moves from the side of lower concentration to the side of higher concentration, balancing the concentration gradient. If a pressure which exceeds the normal osmotic pressure is applied to the solution, the natural flow of the water and hence the osmotic effect can be reversed. The process results in a highly concentrated solution (concentrate) as well as purified water (permeate).

The osmotic pressure depends on the amount of particles dissolved in the feed water. Thus, every type of feed water has its own pressure range for the successful operation of reverse osmosis. Drinking water purification needs one of the lowest pressures (< 10 bar), while landfill leachate treatment demands pressures up to 60 bar or higher.

Disposal of concentrate

The RO concentrate, which contains almost all unwanted particles, must be disposed of externally. The waste disposal costs can be lowered using a high-yield RO plant, which reduces the volume of the concentrate flow. For high yields, subsequent RO stages can be placed in the concentrate flow or the concentrate is returned and mixed with the leachate inflow. If necessary, additional RO stages can be applied for further purification of the permeate stream, e.g., to comply with the discharge limits for ammonium.

Due to the modular system of our plants and years of experience in the field of water treatment with membrane technology, TDL Energie GmbH will find the perfect solution for every kind of waste water.

The concept of reverse osmosis plants of TDL Energie GmbH

Reverse osmosis is a purely physical filtration technique which uses semi-permeable membranes to remove unwanted substances from contaminated waste waters, e.g., landfill leachate. Due to the small pore size of the membranes suspended solids, molecules and even ions can be filtered to produce an effluent water of highest quality suitable for direct discharge.